Difference between revisions of "Custom 3D Tutorial"

(Created page with "==Custom 3D Part== This tutorial will step you through the process of creating a simple part using the Custom 3D interface. To begin, click the New Part icon at the top of ...") |

|||

| Line 5: | Line 5: | ||

To begin, click the New Part icon at the top of the page or click File --> New --> Tube. Doing so will open up the New Design menu. The New Design menu will also automatically open when Bend-Tech starts up. | To begin, click the New Part icon at the top of the page or click File --> New --> Tube. Doing so will open up the New Design menu. The New Design menu will also automatically open when Bend-Tech starts up. | ||

| − | [[File:NewPartIcon.jpg]] | + | [[File:NewPartIcon.jpg]] |

Revision as of 15:26, 2 July 2014

Custom 3D Part

This tutorial will step you through the process of creating a simple part using the Custom 3D interface.

To begin, click the New Part icon at the top of the page or click File --> New --> Tube. Doing so will open up the New Design menu. The New Design menu will also automatically open when Bend-Tech starts up.

In the New Design menu, click the Custom 3D Part option in the Create New Part section.

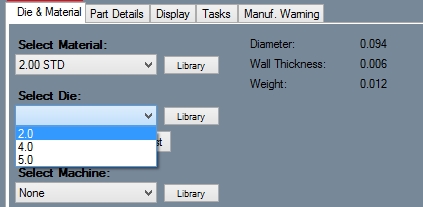

Once Custom 3D Part has been selected, a new Custom 3D Part design window will open. Before designing the part, a material and die must be chosen. In the Die & Material tab, Click the drop down menu below Select Material and choose a material from the list. Click the drop down menu below Select Die and choose a die from the list.

Note: If a default die and material have already been set up, they will already be selected. In that case proceed to the next step.

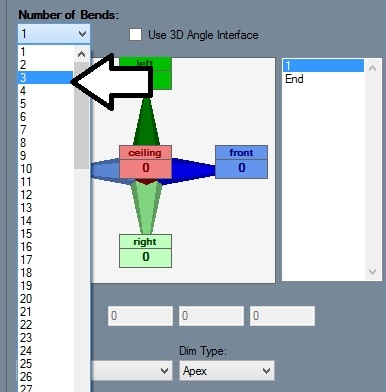

Once a die and material have been chosen, the input interface panel will be available to edit. First, the part's number of bends needs to be selected. Click the drop down menu below Number of Bends and choose 3 from the list.

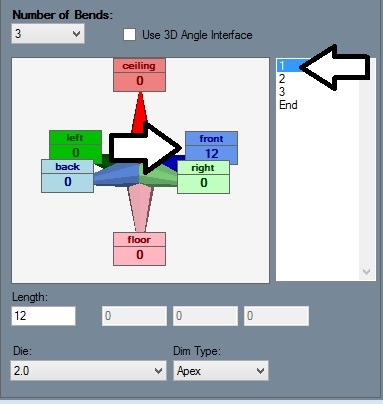

Each bend has 6 directional coordinate fields, but only up to 3 can be entered for one bend and conflicting directions cannot be used at the same time. For example, values cannot be entered into both floor and ceiling for a single bend. Each bend also has a Dim Type and Die drop menu which can be used to change a single die's dimension type or die.

Make sure the box next to Refresh on Keystroke is checked. While this option is enabled, the part display will update automatically as the coordinates are being entered.

Select 1 from the bend list to the right of the coordinate fields. In the coordinate field area, enter 12 into the to front field as shown below.

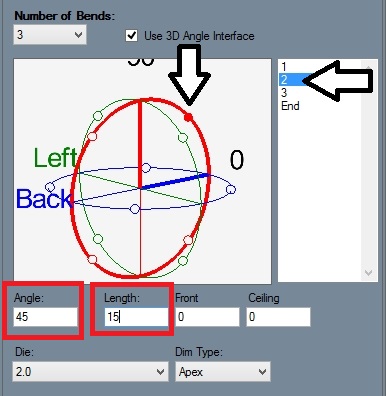

Next, select 2 from the bend list. Check the box next to Use 3D Angle Interface. This will enable the 3D interface for the second bend only. Click the Ceiling-Front point on the Tri-Globe as shown below. Enter 45 into the Angle field and 15 into the Length field.

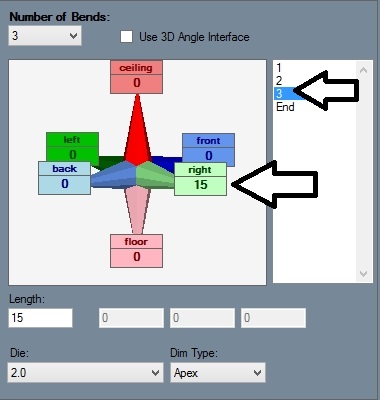

Select 3 from the bend list and enter 15 into the to right field as shown below.

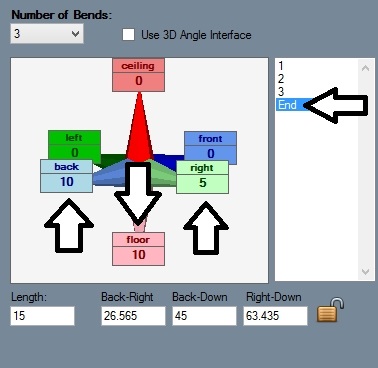

Select End in the bend list and enter 10 into the back field, 10 into the floor field, and 5 into the right field.

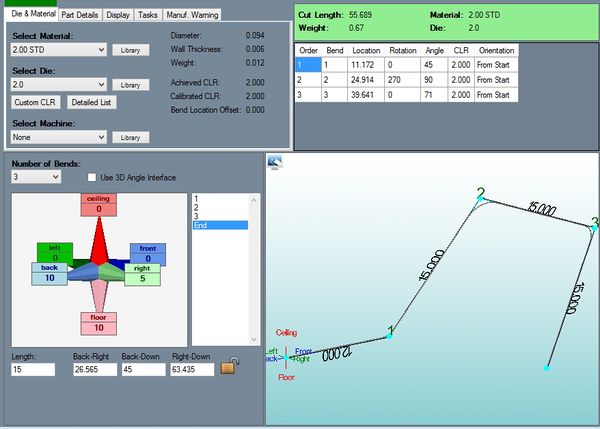

Once all the coordinates have been entered, the part is complete and the window should look similar to the image below. The results table for the complete part is shown in the top right corner.