Assembly

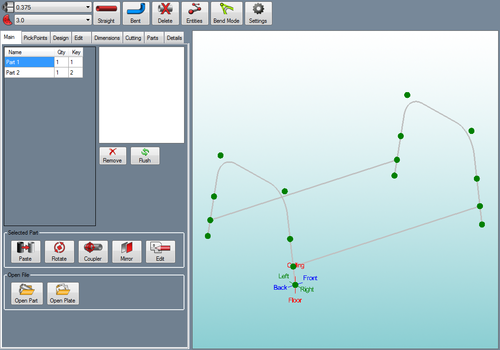

The assembly interface allows a group of different bent and straight parts to be assembled together. Parts created in the single part designers (XYZ, Custom 3D, Sketch 2D, etc.) can be brought into assembly and parts within assembly can be transferred to single part designers. Parts can also be cut and the wrappers for these cuts can be printed out here.

To open a new assembly design:

1.) Go to the File menu, select New Assembly.

2.) Click the New Assembly icon ![]() at the top of the window.

at the top of the window.

...OR

3.) Select the Assembly option from the Task Menu that appears when the software starts up, when all designs are closed, or through the view menu.

Tabs

A majority of the assembly features and functions are located in the tabbed section on the right hand side of the window. To find information about how to use these features, see the links below.

| Main | PickPoints | Design | Edit | Dimensions | Cutting | Parts | Details |

Assembly Menu

When a new assembly window is open, there will be a menu area located above the tabbed section and display frame.

Material

![]() In the material menu, the material for the parts in the assembly can be selected. To select a material, click the drop down menu and choose a material from the list. This material can be changed for each individual part later, this is just the material that is initially applied to new parts. Tube/pipe materials are defined in the Tube/Pipe Library.

In the material menu, the material for the parts in the assembly can be selected. To select a material, click the drop down menu and choose a material from the list. This material can be changed for each individual part later, this is just the material that is initially applied to new parts. Tube/pipe materials are defined in the Tube/Pipe Library.

Die

![]() In the die menu, the die used to bend the parts in the assembly can be selected. To select a die, click the drop down menu and choose a die from the list. This can be changed for each individual part later, this is just the die that is initially applied to new parts. Dies are defined in the Die Library.

In the die menu, the die used to bend the parts in the assembly can be selected. To select a die, click the drop down menu and choose a die from the list. This can be changed for each individual part later, this is just the die that is initially applied to new parts. Dies are defined in the Die Library.

Straight

To create a straight tube between two PickPoints, click the Straight button  and click any two PickPoints or Auto points (points that are automatically generated along parts, such as mid points, apex point, or start and end of bend points ) in the display window.

and click any two PickPoints or Auto points (points that are automatically generated along parts, such as mid points, apex point, or start and end of bend points ) in the display window.

Bent

To create a new bent part, click the Bent button.  In the Number of Bends window that appears, enter the number of bends that the part will have and click the OK button. To create the part, you must select the start point and the location of each bend, and the end point of the part. You cannot create a bend that is 180° or more by using the Bent Part tool. In order to create such a bend, you would need to create two separate parts.

In the Number of Bends window that appears, enter the number of bends that the part will have and click the OK button. To create the part, you must select the start point and the location of each bend, and the end point of the part. You cannot create a bend that is 180° or more by using the Bent Part tool. In order to create such a bend, you would need to create two separate parts.

Delete

To remove a part from the assembly, first click on the Delete button. Then in the design frame, click on a part to delete it.

Entities

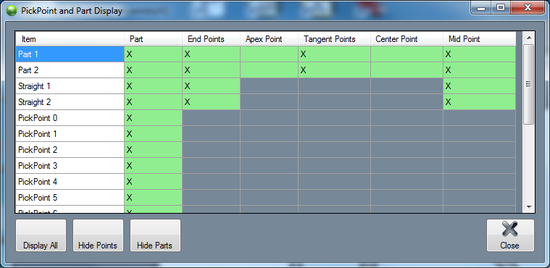

The Entities tool controls which parts and points are displayed in the assembly. Click the Entities button  to open up this menu. Each row will represent straight part, bent part, and PickPoint. To hide a certain feature, click in the green box to remove the X. To have all features shown, click Display All button.

to open up this menu. Each row will represent straight part, bent part, and PickPoint. To hide a certain feature, click in the green box to remove the X. To have all features shown, click Display All button. ![]() To hide all PickPoints, click the Hide Points

To hide all PickPoints, click the Hide Points ![]() button. To hide all parts, click the Hide Parts button.

button. To hide all parts, click the Hide Parts button. ![]()

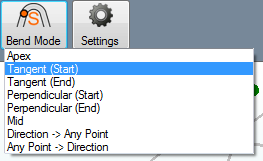

Bend Mode

This option controls what kind of bend location will be for future bent parts in the assembly (In other words, this setting will not affect current parts).

Apex: Measures to the outside intersection (apex) of the bends two legs.

Tangent (Start): Measures to the start of the bends, the tangents, so no bent material will be included in the measurements.

Tangent (End): Measures to the end of the bends, the tangents, so no bent material will be included in the measurements.

Perpendicular (Start): Measures to the tangent plus the CLR of the bend.

Perpendicular (End):

Mid:

Direction -> Any Point:

Any Point -> Direction:

Settings

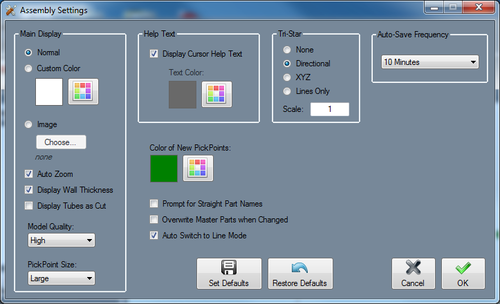

These settings are used to control the display and general options within the current assembly.

Main Display

The main display settings control the part display and part model appears in the assembly interface. The background of the main display can be shown.

- Background: Select the Normal option for the part display background to be shown with the normal blue to white gradient. Select the Custom Color option to choose a custom solid color. Select the Image option to select an image file to display as the background.

- Auto Zoom: Check this option to automatically zoom all the way in on the current view of the 3D part display and fit it to the display frame.

- Display Wall Thickness: Check this option to have the thickness of the material shown on the part model when in shaded mode.

- Display Tubes as Cut: Check this option to have the profiles of any cuts on the tubes represented on the part model.

- Model Quality: To adjust the graphic quality of the part model, select an option from this menu. Parts can be shown in high, medium, and low quality.

- PickPoint Size: To adjust the size of all the pickpoints shown in the display frame, select an option from this menu.

Help Text: Check the box next to Display Cursor Help Text to toggle the help text on and off in assembly. This help text will help guide certain processes within assembly. The color of this text can be adjusted using the Text Color option.

Tri Star

These options will control how the tri-star will appear in the current assembly design. The tri-star can be Directional (labeled with ceiling/floor, front/back, left/right), XYZ (labeled with X, Y, and Z), Lines Only, or None (not shown at all). The default scale value can also be defined here, which will control how large the tri-star will appear.

Color of New PickPoints: The default color of new PickPoints can be adjusted here. Click the color button and select a color from the menu to choose a new PickPoint color.

Prompt for Straight Part Names: While this option is checked, every time a new straight part is added to the assembly, a window will prompt for a name to be given to this part instead of defaulting to "Straight 1" for example.

Overwrite Master Parts when Changed:

Auto Switch to Line Mode: Check this option to have the display mode automatically switched to line mode whenever new points or parts are being added/edited in the current assembly design.

Auto-Save Frequency: The time interval between the automatic saves can be adjusted using this menu.

Set Defaults: Click the Set Defaults button ![]() to use these settings as the defaults for future assembly designs.

to use these settings as the defaults for future assembly designs.

Restore Defaults: Click the Restore Defaults button ![]() to reset all the settings to the default selections.

to reset all the settings to the default selections.

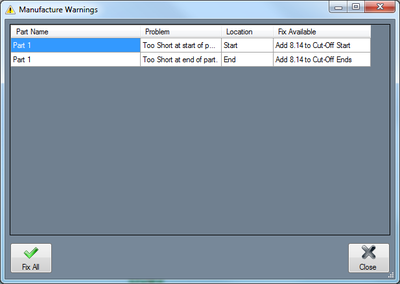

Manufacture Warnings

If any problems are found with a part, a warning icon ![]() will appear at the top of the assembly window. If this icon is clicked, manufacturing warnings will be listed. These warnings are based on the die limitations applied to the current die used to bend the part(s). These limitations can be defined in the Die Library. The part name, a short description of the problem, location, and fix (if available). If an auto-fix is available, double-click on the auto-fix description to execute the auto-fix. Click the Fix All button

will appear at the top of the assembly window. If this icon is clicked, manufacturing warnings will be listed. These warnings are based on the die limitations applied to the current die used to bend the part(s). These limitations can be defined in the Die Library. The part name, a short description of the problem, location, and fix (if available). If an auto-fix is available, double-click on the auto-fix description to execute the auto-fix. Click the Fix All button ![]() to fix all problems with a fix option available.

to fix all problems with a fix option available.